The DANIELI FRÖHLING‘s 6-High Mill Stand Technology is a high flexibility Cold Mill stand that not only allows for improved performance and product quality, but also enables to fulfill the most demanding applications such as thinner gauge, improved flatness profile, and rolling of higher strength materials.

On top of the features of a 6-High Mill is that it has a more complex adjustment range to setup the roll gap profile with the additional bending and shifting functions of the intermediate rolls. This allows for an adaption to a larger variation of incoming product widths and profiles, more dynamic flatness adjustment range, and highest level of strip flatness performance. The configuration ensures the flexibility to schedule rolling current products as well as future products.

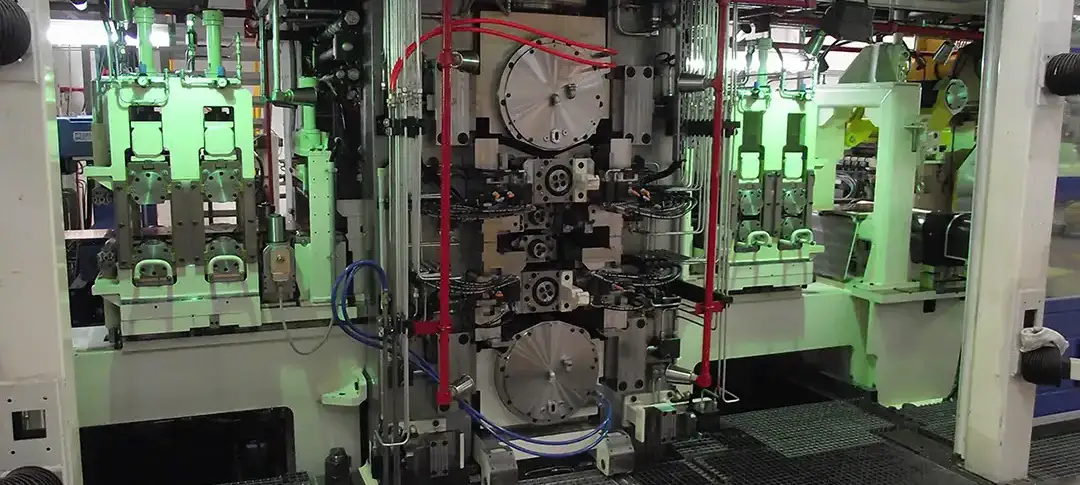

The 6-High Mill Stand supplied by Danieli Fröhling is designed to apply positive and negative bending, both for work rolls and intermediate rolls, in a fully symmetrical design. Long stroke lateral shifting is implemented to the intermediate rolls. Fixed or variable horizontal roll offset is used for the stabilization of roll stack and minimization of work roll horizontal deflection. Sectional cooling is applied for precise thermal control of the rolls, matching roll cooling to the requirements of temperature balance and flatness control.

Direct Contact

Frank Otterbach