SPECIALTY Rolling Mills

Intensive research on new alloys, or product and metallurgy optimization is in most cases not feasible on industrial rolling mills, as they are in continuous production without possibility of time-consuming experiments. The laboratory mill is a miniaturized industrial mill, featuring similar process conditions as applied in large scale industrial installations.

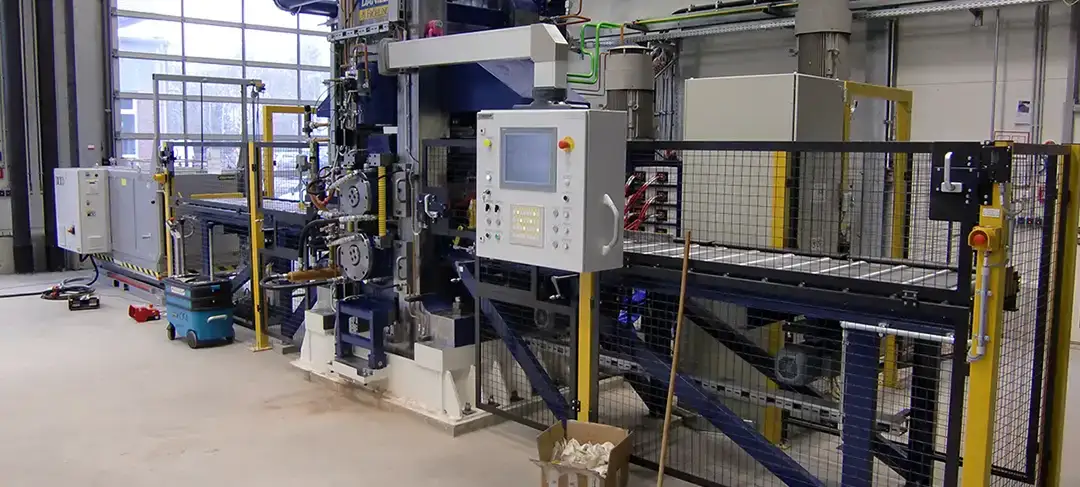

The Laboratory Rolling Mill is either a 2-High or a combined 2/4-High design with direct hydraulic gap control. The 2-High mode is used for Hot or Cold Rolling with large roll diameters, while the 4-High mode can be used for thin gauge Cold Rolling with small work roll diameter.

Additional features can be installed to cope with variation of process parameters, i.e. work roll twin drive for asymmetrical rolling, work roll heaters to simulate industrial process roll temperatures, roll lubrication system for variable type of oil or emulsion to simulate friction conditions, and the like.

Special materials like magnesium, zirconium, silver, molybdenum and the like, are produced in small quantities, but in huge variations of product dimensions. Hence, the Rolling Mill shall have a large flexibility in terms of alloys and finish product appearance. Due to the limited market request and availability of such materials, all of those requirements shall integrate in one single Rolling Mill. Optionally, finished sheets can also be cut-to-length in-line to provide for end customers‘s product sizes.

Direct Contact

Frank Otterbach