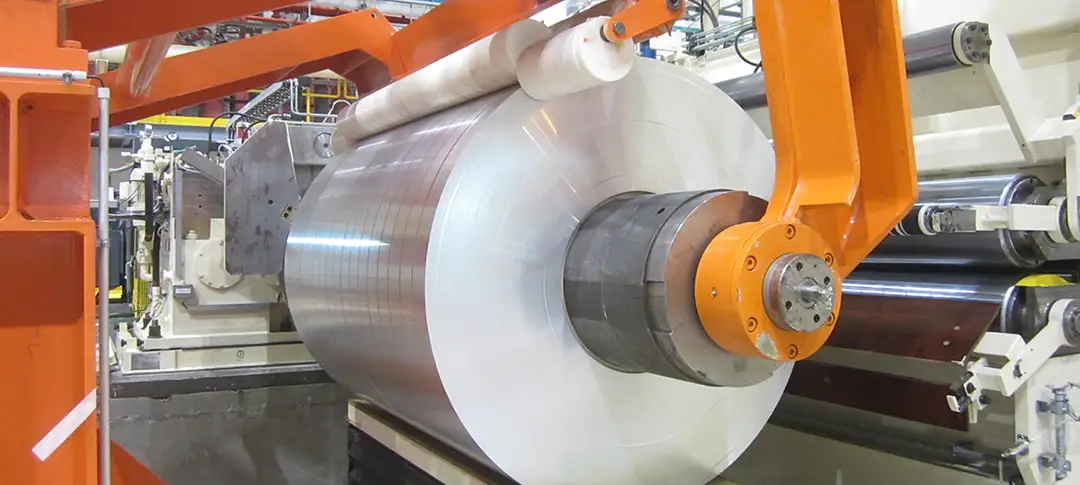

Our slitting lines for metal strips belong to the highest class of equipment in this particular section of plant and machine building. We supply slitting lines for steel, aluminium, copper, brass, bronze and other special metals and alloys. Strip width ranges between 200 mm and 2,800 mm and strip thickness may be between 40µm and 10 mm. Solutions for dimensions exceeding the mentioned range are subject to further discussions.

Danieli Fröhling slitting lines may be equipped with conventional eccentric shears or highly precise CNC (computer numeric controlled) slitting heads. The chosen solution depends on material dimensions and customers’ requirements. For sensitive and thin material (up to approx 1 mm thickness), vacuum brake rolls may be used. Vacuum roll technology has been developed by Danieli Fröhling and a large number of applications have been in use for years at different customers. Vacuum roll technology is further used as pinch units or as double-loop builder. Obviously, we have a vast experience with other conventional tensioning systems as well.

The perfect cut and the perfectly wound coil take the center of all our efforts with respect to slitting. Danieli Fröhling is technologically leading in many aspects and was always setting benchmarks that became synonymous for advanced slitting technology. Moreover, optimization of plant productivity and handling as well as energy efficiency become important for us to serve our customers even better. Solutions available are for instance:

- Automatic sequences for loading and unloading of coils

- Automatic threading

- Machine adjustment according to strip properties based on recipes stored in the automation system

- Automatic tool changing

- Reliable scrap removal

- Recovery of energy from coilers and brake rolls

- Automatic looping pit control

- Optimized deflector roll sizes according to material to be processed

- Automatic (or semi-automatic) change of coiler mandrels and automatic clamping of the latter

- Suitable packaging lines for slit coils with different configurations and automation degrees

Leading strip producers around the world rely on Danieli Fröhling’s slitting technology. Flexible line configurations exactly meeting the particular application but at the same time being easily adaptable for future market changes are our specialty. We do not sell off-the-shelf: We do it tailor-made for you! Contact us for detailed discussions and explanations.

Direct Contact

Leander Zielenbach