DANIELI Service

The focus is on the highest quality, productivity and low operating costs paired with customer-oriented after-sales service by our own specialists and local workshops.

Our Vision

… is to improve the performance of our customers in close cooperation. For this we offer global solutions based on state-of-the-art equipment and digital systems.

Our Mission

THE FOUR PILLARS

Small modernizations and improvements

Original spare and wear parts

High technology products

Extended service: On-site technical support, reconditioning and training

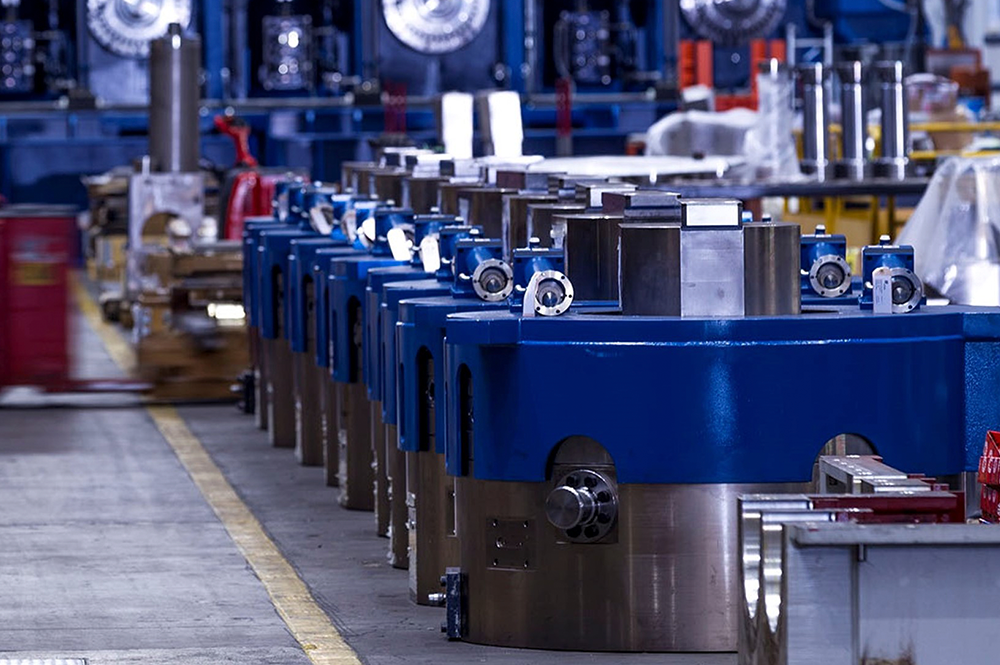

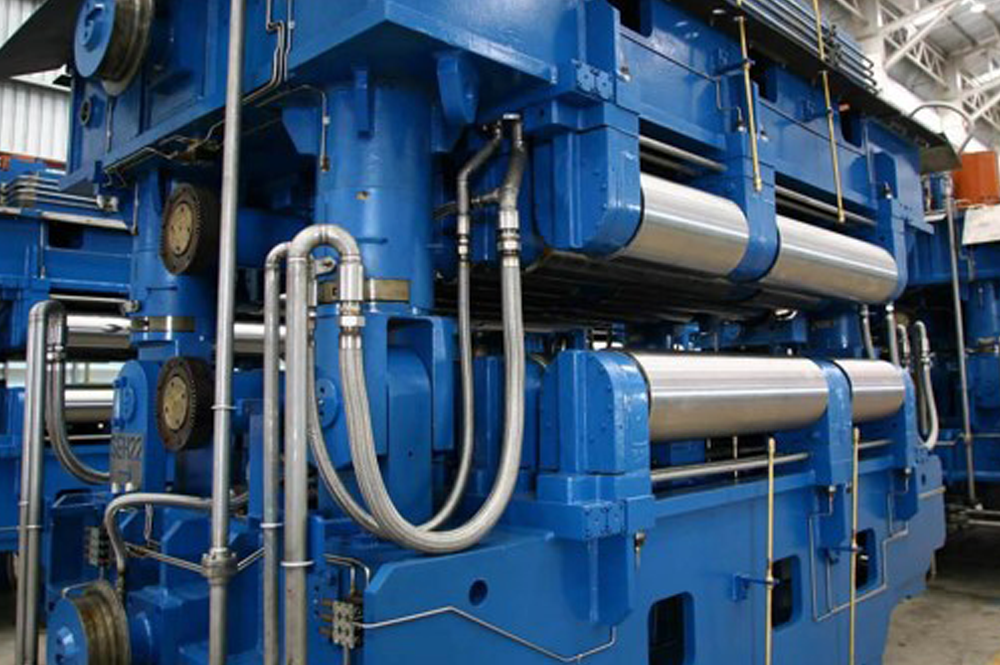

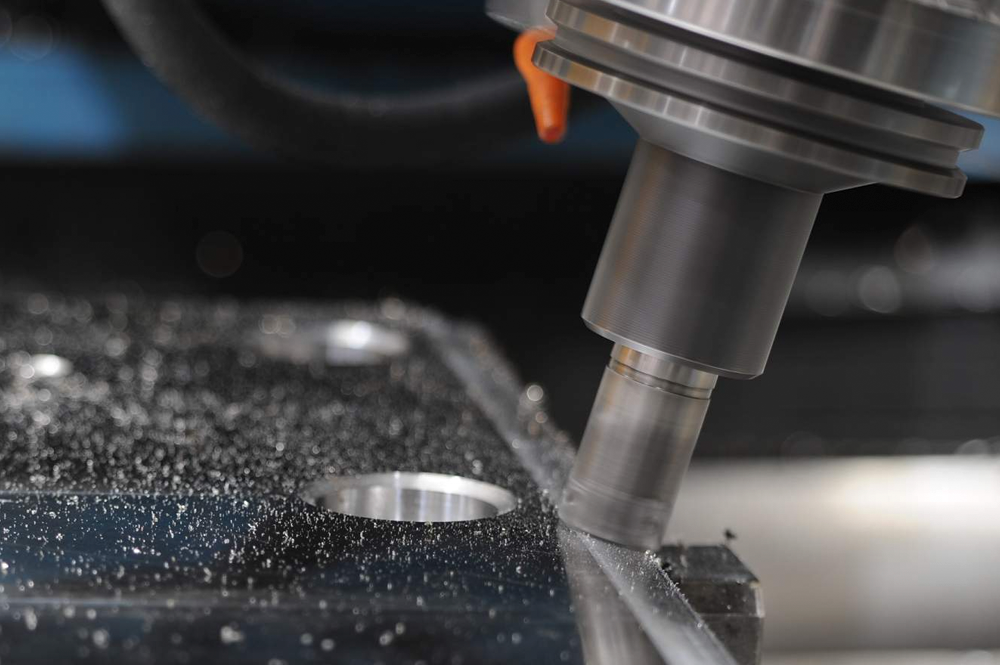

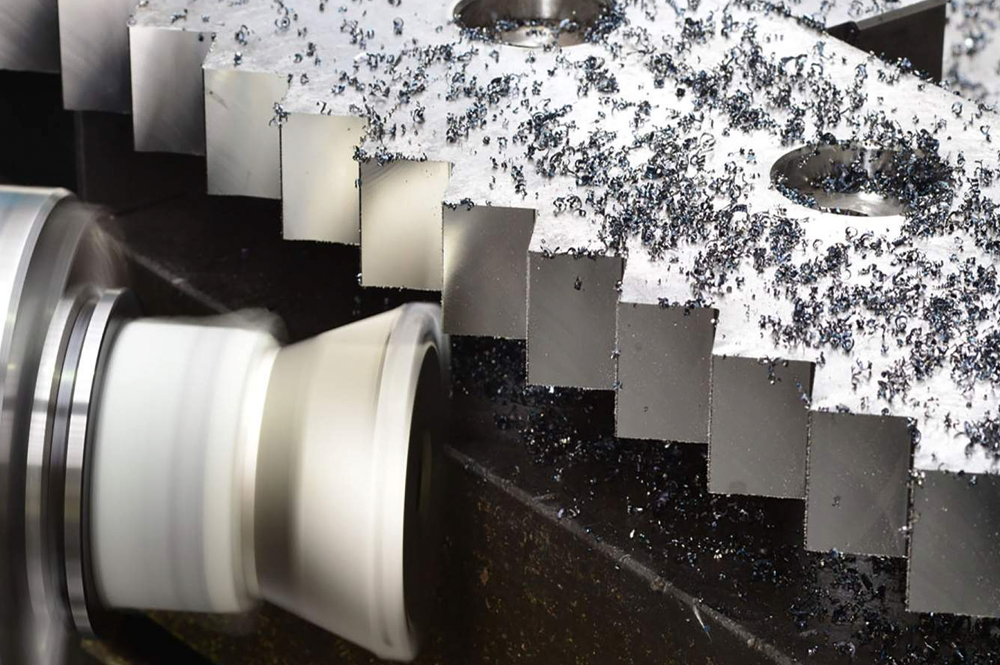

Specialized Workshop

With a specialized workshop for rolling mills and strip finishing lines, DANIELI Germany GmbH ensures the advanced DANIELI quality for new installations, as well as repair and maintenance works.

Quality engineering and manufacturing – Made in Germany

With a total working area of 4,200 m² in Meinerzhagen and a workshop area of 2,800 m², it is the sixth largest of all DANIELI workshops. In average over the recent years, approx. 600 tons per year of material have been further processed through the workshop. Furthermore, service assignments for repairs and maintenance on customer sites all over the world are performed.

The main tasks and competences

Consulting

Assembling

Automating

Manufacturing

Revamping

Upgrading

Transporting

What we count on

We lift

Tons of maximum load

We process

Tons of material per year

We work on

Area in m²

The workshop is certified according to:

ISO 9001 : 2015

ISO 45001 : 2018

ISO 50001 : 2018

Technological Packages – “Small Investments Big Results”

With our technological packages, DANIELI supports all customers in reaching their goals of environmental sustainability, work safety and improved final product quality, through technological innovation and a quick return on investment.

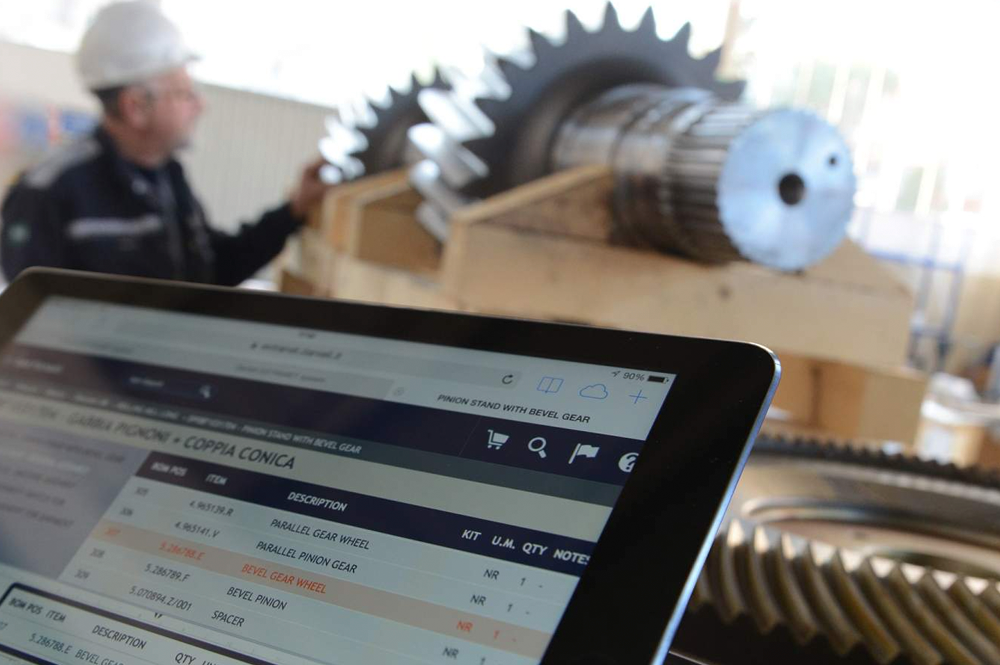

Customized Solutions with Original Spare and Wear Parts

Continuous maintenance as well as the availability of spare parts are essential for a smoothly working machine. No matter, if machine parts have to be produced particularly for a certain line or as standard elements of other suppliers: Our team advises and provides you with a customized offer.

Thereby, “Original Spare Parts of Danieli” always stands for quality and reliability.

Do not hesitate to contact us, no matter if it concerns standard parts of machines like bearings, valves, cylinders or electrical parts. We are able to provide a competitive offer, as we are well connected with our OEM’s.

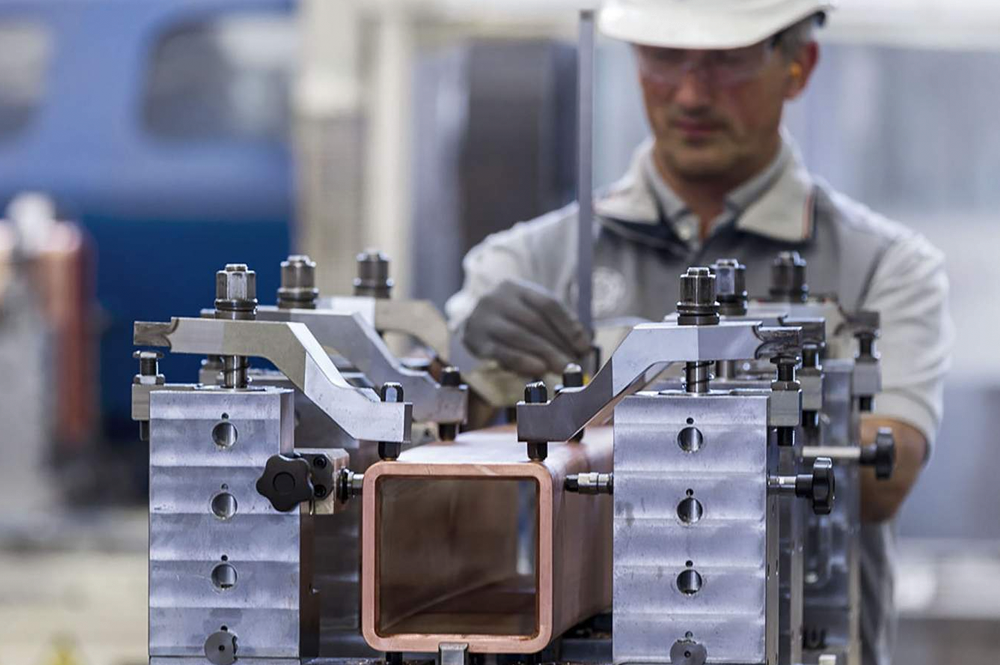

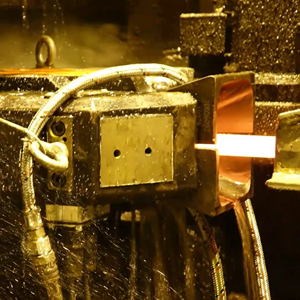

High-tech Products

DanOil – Oil film bearing and plant components

Q-Roll - Danieli slab caster rolls

DANIELI copper elements for steel casting

DanLiner – Double layer mill liners

Mandrels for flat applications

DANCut – Shear blades for metal industry

Keep the World Rolling

Since introducing a revolutionary roller guide product in 1945, DANIELI Morgårdshammar has been leading the international steel industry and introducing a number of patented products for rolling mill systems. These original concepts have been developed continuously in order to meet the current market requirements. The quality of DANIELI Morgårdshammar`s guide products are world famous for its strength and durability, and the guide systems suit most type of rolling mills.

The latest intelligent guides have remote control with real-time feedback of the rolled section, in order to improve the rolling mill safety, quality, and reliability. This technology, patented by DANIELI Morgårdshammar, represents a paradigm shift in the approach to entry guiding: The Intelligent Guides RX and WSG Series are the long-sought “self-adjusting guides”.

Intelligent Guides

Bar and Rod Mill

Roughing Mill

WRB / Finishing Mill

Profile / Section Mill

Twist / Slit Guides

Setting Equipment

Rollers

DANIELI Morgårdshammar

DANIELI Morgårdshammar DANIELI MORGÅRDSHAMMAR AB is an engineering company, specialized in rolling mills for long products in the steel industry. It has been supplying rolling mill equipment and consulting services to steel producers for over 150 years. The process knowledge of steel plant is earned from extensive experience and together with the DANIELI Group, Morgårdshammar AB is able to provide tailored products and services to all customers who need to improve their business efficiency.

On-site technical support, reconditioning and training

Every technical system has to be checked and maintained on a regular base. DANIELI operating manuals inform and guide the customer to perform each maintenance in most professional way.

DANIELI Germany offers maintenance assistance by professional engineers, who come to customer site or workshop in order to support or conduct the maintenance procedure. In case of a machine breakdown, DANIELI professionals are at your disposal to repair and to overhaul the machine as well as to replace the damaged parts.

As soon as it comes to modernization potentials of assembly units or presenting ways to increase the capacity from anterior plants, DANIELI professional engineers will discuss all options with our customers. They explain the latest developments for the respective application and check individual modifications exactly on the corresponding machine.

Beyond that, there is the possibility of a training at your plant or site in order to refresh and to extend the competence and the knowledge of qualified persons, operators and maintenance personnel. Such kind of training refers not only to the machine and its maintenance, but also, if requested, includes technological aspects of cutting and rolling technologies and peripheral process as well.

At DANIELI, we are aware that know-how reflects not only technological process and design, but manufacturing capability as well. The fact that we have overall control of our projects from in-house design and manufacturing to on-site start-up and commissioning creates an ideal virtual loop that consistently feeds Danieli’s technological knowledge base, and results in guaranteed quality and reliability.

Technological consultancy examples

Technological consultancy examples- Analysis and optimization of rolling process and roll grinding

- Analysis and elimination of flatness problems by optimizing the use of flatness actuators

- Root cause analysis of surface defects (resonances, chatter marks)

- Pass schedule optimization

- Training (form deviations and their definition, causes and suggestions for avoidance)

- Analysis and optimization of slitting machines

- Root cause analysis and removal of cutting burr and tolerance errors

- Optimization of set-up times and non-productive times in general

- Recommendation of new technologies for quality improvement and / or increase in productivity

Direct Contacts